|

Specifications

|

|

Catalogue

|

Chemical Material | High temperature Blowing Agent | AC Blowing Agent & Azodicarbonamide

|

|

Alias

|

Azodicarbonamide,AC Foaming agent,Azobisformamide,ADC

|

|

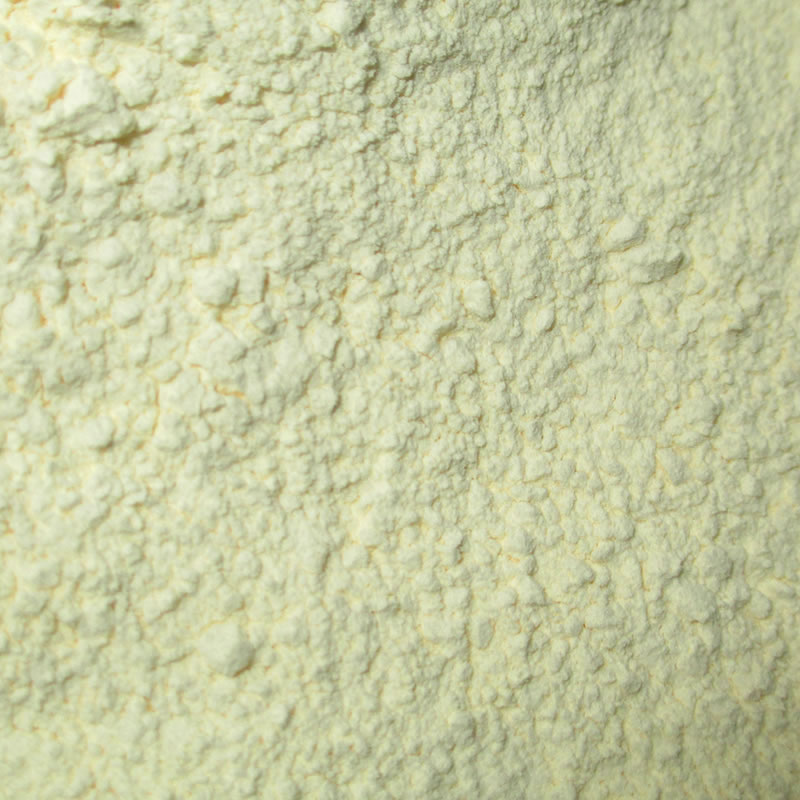

Appearance

|

Yellow Powder

|

|

Brand

|

MXHAPPY

|

|

Package Type

|

Carton Box 25Kgs,

|

|

Item No.

|

AC1000

AC3000

AC5000

AC7000

|

|

Particle size

|

AC1000 10~12um

AC3000 8-10um

AC 5000 6-8um

AC7000 3-5um

|

|

Molecular formula

|

C2H4N4O2

|

|

Molecular weight

|

116.08

|

|

CAS No

|

123-77-3

|

|

EC No

|

204-650-8

|

|

UN No.

|

3242

|

|

Gas evolution (STP)

|

225±5ml/g

|

|

Decomposition temp. ,°C,≥

|

205

|

|

Heating decrement, %≤

|

0.25

|

|

Ash, % ≤

|

1.00

|

|

Purity,%,≥

|

98.0

|

|

Application

|

Azodicarbonamide/AC blowing agent is high temperature chemical foaming agent. Widly used on plastic

and rubber foam,suchas the PE (IXPE), PS, EVA, PVC, and NBR, SBR, and rubber mixture is especially

suitable for PVC coating.

|

|

Lead Time

|

Usually 30 Days

|

|

Description

|

Feature

|

|

|

Technical Data Sheet

Product Name:AC Blowing Agent, Foaming Agent , Azodicarbonamide

Product Introduction:ACP-W foaming agent is used widely in the foaming of EVA, PE,PVC,natural rubber, synthetic rubbers, PVC+NBR blending and other materials. It is particularly suitable to the hot-pressing molding of EVA MD in large and small molds.

Characteristics:Foaming at low temperature; High Whiteness of final products; Stable foaming ratio; Excellent elasticity of products

Item No.: AC1000

Cas No: 123-77-3

Molecular Formula: C2H4N4O2

UN Number.: UN3242

Technical Index

Main chemical component: Azodicarbonamide

Appearance: Light yellow powder

Decomposing Temperature ℃ :200-210

Gas Volume ml/g :215-225

Particle size (μm): 10-12

Ash: ≤0.3%

Moisture: ≤0.3%

Application

AC 1000 with low decomposing temperature, no activator is needed to activate its decomposition. Lessen the using of foaming activator will not only reduce the cost, but avoid mottles produced. It is best fit for the production of pure white products. It could also save a large number of pigments while using in the colored products, and make the product brighter and more vivid. The product will have fine bubble structure from using this foaming agent. The outstanding feature is that this foaming agent could produce whiter high quality EVA shoes material without affecting other physical performance of products.

Suggest to use ACP-W in lower mixed temperature and general sulfuration condition to avoid the uneven cellular, coarse cellular or other problems because of premature foamed. In most cases, foaming activator is active oxidant, which will affects the excellent elasticity of polymer chains for EVA and other material. This series foaming agent is favor for the tensile and tearing strength of products, especially benefits to the elongation of products.

Package and Storage

It is odorless and non-toxic, with good storage stability and won’t decompose under common temperature but should be stored in a cool, dry place away from any sources of heat, spark, open flames or direct sunlight. Never let it contact directly with acids or alkalis. Good local exhaust ventilation in mixing and handling areas is highly recommended. Be careful not to inhale its powder, make frequent skin contact or swallow it.

Each 25kg of this foaming agent is packed in plastic lined bag or carton according to clients’ demand.

Each batch of this foaming agent series weighs 3 Tons. While using the foaming agent of same batch, only a small quantity is needed to test for confirmation and then the whole batch can be used with certainty.

|

ID

ID VN

VN US

US SG

SG